UnitedAxle

UA375325ST-LI (DA/R Inner Bearing Journal)

UA375325ST-LI (DA/R Inner Bearing Journal)

Couldn't load pickup availability

The spindle tester gage measures slightly larger than the spindle in the center so it can slide onto the spindle end. Once it is slid onto the spindle where the bearing sets, the tool can be used by moving it side-to-side. This tool should be used delicately with a thumb and "two-finger" hold. The tool should not be forced onto the bearing journals.

Bearing journals should be checked horizontally, vertically and diagonally. On one side of the tool you will see the word "GO" and on the other side of the tool are the words "NO-GO" which indicates there is more than 0.006" wear which is an indicator the spindle should be further inspected and may be in need of spindle replacement.

The design of the tool makes it easy for technicians to quickly check the spindle wear of spindles. The tool is made of aluminum and is lightweight. The tool is machined with very tight tolerances and measures out to the thousandths. The tool should be stored and cared for properly and kept in climate controlled facilities with temperatures ranging from 65-85 degrees.

The spindle should be checked side-to-side and then turned in a clockwise direction around the spindle to check all directions for spindle wear. Generally, the wear will be found on the underside of the spindle. If at any time the tool moves to the "NO-GO" side when attempting to slide the tool back and forth around the bearing journal area - THE SPINDLE SHOULD BE FLAGGED AND INSPECTED FURTHER FOR REPLACEMENT.

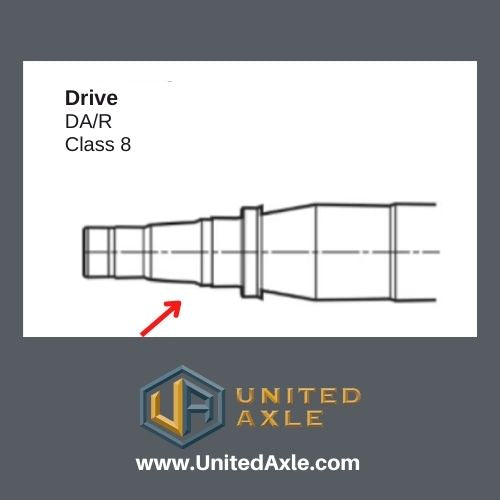

PART NUMBER: #UA375325ST-LI spindle tester gage fits the Drive (Class 8) inner bearing journal.

Materials

Materials

Aluminum

Shipping & Returns

Shipping & Returns

All orders will be shipped ground.

RETURN POLICY:

10 day money back guarantee less shipping. Buyer is responsible for return shipping fees. Please contact United Axle @ 844-774-6353 for RA# and return shipping instructions.

Dimensions

Dimensions

8" x 10"

Care Instructions

Care Instructions

Use & Storage:

Tester gages are inspected and certified in a climate controlled facility to ensure accuracy prior to shipping. All tester gages should not be stored in extreme temperatures and kept between 65-85 degrees to maintain accuracy for measurement.

Gages should not be forced on the spindle as this could damage the measuring edge and damage the tester gage.